Leeuwenhoek Saison Yeast Blend

WLP564Pitch Rate Calculator

Curious about brewing with this strain? White Labs Brewing Co has the data you need!

Matched keywords: 4

Belgian Saison I Ale Yeast

WLP565Pitch Rate Calculator

Curious about brewing with this strain? White Labs Brewing Co has the data you need!

Matched keywords: 4

Belgian Saison II Ale Yeast

WLP566Pitch Rate Calculator

Curious about brewing with this strain? White Labs Brewing Co has the data you need!

Matched keywords: 3

Saison/Brettanomyces Yeast Blend II

WLP4636Matched keywords: 3

WLP546 Marañón Canyon Wild Cacao Yeast: A rare, exclusive Fermentation Society release

Fermentation Society is all about exploring new realms and possibilities. Check out the rediscovered strain of a cacao bean and use the yeast to brew in time for Valentine's Day!

WLP546 Marañón Canyon Wild Cacao Yeast

Sign up for Fermentation Society, Enrollment is free!

White Labs has teamed up with Marañón Chocolate to isolate and produce a unique yeast from a rare cacao variety—Pure Nacional—that was once thought to be extinct in Peru. The strain, WLP546 Marañón Canyon Wild Cacao, has now been released to customers for brewing beer.

The coveted cacao bean was rediscovered in late 2007 by Dan Pearson and Brian Horsley, founders of Marañón Chocolate, while sourcing tropical fruits in the remote Marañón Canyon of Northern Peru. Not knowing what they stumbled upon, the pair sent the cacao tree leaves to the USDA Genetics Laboratory. USDA confirmed it was the same variety that had once dominated the chocolate market, but vanished in 1916 when diseases struck and killed the trees that grew these cacao beans.

QUICK FACTS

- Name: WLP546 Marañón Canyon Wild Cacao

- Style Recommendation: Farmhouse/Saison

- Alcohol Tolerance: Medium (5-10%)

- Attenuation: 65-70%

- Flocculation: Low

- Optimum Fermentation Temp: 65-75℉ (18-24℃)

- Strain Description: This yeast was isolated from the thought to be extinct Pure Nacional variety of cacao. In 2007, this rare variety with white beans was rediscovered in the remote Marañón River Canyon in Peru. The fruity, phenolic, and wild-like characteristics of this strain make it an ideal choice for farmhouse and saison-style beers.

Then, in 2015 and 2016, El Niño weather systems hit Peru, impacting the wild yeast responsible for the beans renowned characteristic flavor. To preserve the wild microflora, Pearson reached out to Kara Taylor, technical laboratory manager at White Labs, to see if the international yeast company could capture the wild yeast from fermenting beans. They succeeded.

“After they successfully isolated the wild cacao yeast, our next thought was ‘can you make beer with it?’” said Pearson. “So I asked Kara if she thought it was possible, and she told us that the odds of isolating and stabilizing a wild yeast were very slim, but that they would try, and fortunately for us, they did!” “I was skeptical that we would find a wild yeast on the cacao that had the capabilities to ferment beer,” noted Taylor. “We love to find yeast in unique places, but it’s unusual to find yeast that will ferment maltose while tasting and smelling good. In this case, we found a unique strain that creates a farmhouse type aroma and flavor profile.”

On top of isolating and propagating this cacao yeast, White Labs also brewed a test batch of beer which captured the esteemed fruit, floral and spicy flavors that the chocolate is known for producing. White Labs found that WLP546 Marañón Canyon Wild Cacao produces fruity, phenolic, and wild-like characteristics that make it an ideal choice for farmhouse and saison-style beers.

WLP546 Marañón Canyon Wild Cacao is being released now through the White Labs Fermentation Society while supplies last!

BUY NOW

Did you know?!

Chocolate is fermented! When cacao beans are harvested, the bean and white pulp are fermented in a large vat. By allowing the natural microbes undergo fermentation on the beans, it can help transform the bitter not as appetizing bean into something more rich and complex. The microbes will break down carbohydrates into simple sugars, allowing sweet caramelization during roasting. Most of the different fruity aromas and appeasing characteristics come from fermentation. They will also produce some alcohol taken up by acetic acid bacteria to produce acetic acid. This acid helps change certain components of the cacao bean, creating even more depth and complexity.

Matched keywords: 3

Belgian Style Saison Ale Yeast Blend

WLP568Pitch Rate Calculator

Curious about brewing with this strain? White Labs Brewing Co has the data you need!

Matched keywords: 2

Belgian Saison III Ale Yeast

WLP585Pitch Rate Calculator

Curious about brewing with this strain? White Labs Brewing Co has the data you need!

Matched keywords: 2

French Saison Ale Yeast

WLP590Pitch Rate Calculator

Curious about brewing with this strain? White Labs Brewing Co has the data you need!

Matched keywords: 2

Saison/Brettanomyces Yeast Blend I

WLP4626Matched keywords: 2

Marañón Canyon Wild Cacao Yeast

WLP546

This yeast was isolated from the thought to be extinct Pure Nacional variety of cacao. In 2007, this rare variety with white beans was rediscovered in the remote Marañón River Canyon in Peru. The fruity, phenolic, and wild-like characteristics of this strain make it an ideal choice for farmhouse and saison-style beers.

Learn more about this strain in our blog

Use in conjunction with a higher attenuating strain for faster fermentation or higher attenuation.

(Suggested strains: WLP001, WLP550, *WLP590 *STA1+)

Fermentation Society Exclusive Strain Releases

Exclusive access to strain releases from our vault. Each release includes a collectible pin and strain card that are only available to those members that receive this unique strain. Collect them all to show off your expansive zymurgy experience! Join Fermentation Society Today!

*Exclusive only for Fermentation Society Members. One per order while supplies last!

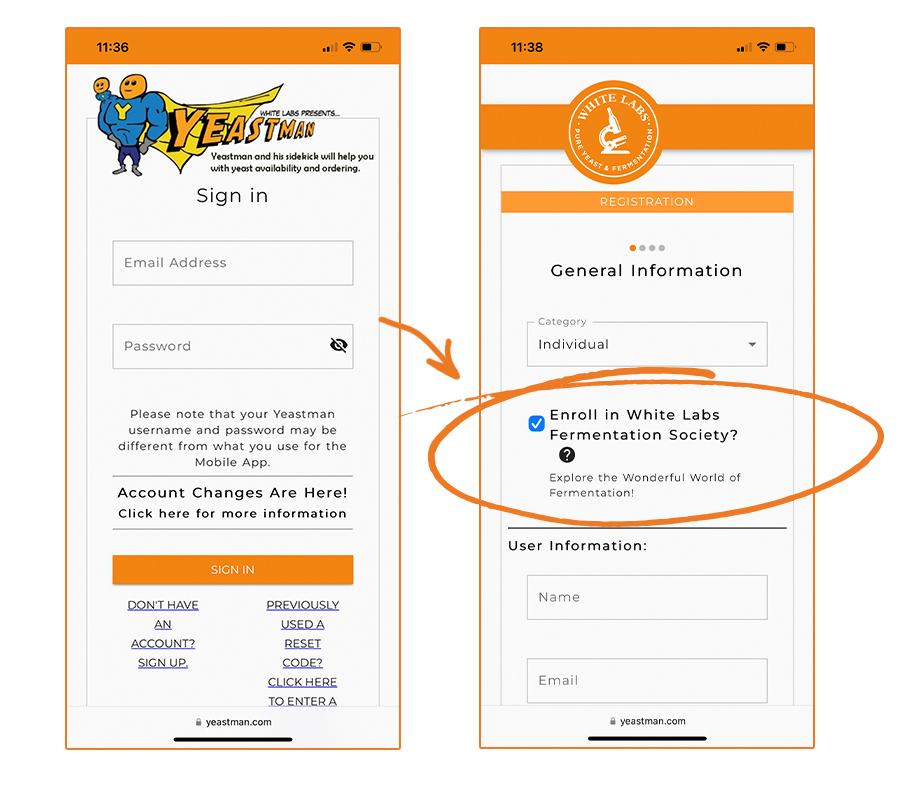

How to Join

- New Users to Yeastman

- Go to yeastman.com and select, “Don’t have an account yet? Sign-up!” to begin creating your new account

- Select Individual in the category dropdown

- Enter your information into the general information page, no credit card information required

- Be sure to Check “Yes” in the “Enroll in White Labs Fermentation Society” drop-down box

- Complete the remaining new account registration pages and you are now a member of the White Labs Fermentation Society!

- Users with Existing Yeastman Accounts

- Log-in to your Yeastman account by entering your email address and password

- On the left tab, select My Account

- Click on the drop-down box under “Enroll in White Labs Fermentation Society” and select “Yes”.

- You are now a member of the White Labs Fermentation Society!"

Curious about brewing with this strain? White Labs Brewing Co has the data you need!

Matched keywords: 1

Belgian Ale Yeast

WLP550Pitch Rate Calculator

Curious about brewing with this strain? White Labs Brewing Co has the data you need!

Matched keywords: 1

Non STA1son Ale Yeast Blend

WLP561Pitch Rate Calculator

Curious about brewing with this strain? White Labs Brewing Co has the data you need!

Matched keywords: 1

Torulaspora delbrueckii

WLP603Attenuation ranges will vary depending on recipe and/or mash profile

Quick Tips for brewing Non-Alcoholic And Low Alcohol Beer

Best Practices for Brewing Low Alcohol/Non-Alcoholic Beers, Part 1

Best Practices for Brewing Low Alcohol/Non-Alcoholic Beers, Part 2

Non-Alcoholic/Low Alcohol Tech Sheet

Pitch Rate Calculator

Matched keywords: 1

New Nordic Ale Yeast

WLP611Pitch Rate Calculator

Matched keywords: 1

Saison Ale Yeast Blend I

WLP4007Matched keywords: 1

Saison Ale Yeast Blend II

WLP4021Matched keywords: 1

Wallonian Farmhouse III Ale Yeast

WLP4023Matched keywords: 1

Farmhouse Sour Ale Yeast Blend

WLP4675Matched keywords: 1

Quick Tips for Brewing Non-Alcoholic and Low Alcohol Beer

Non-Alcoholic and Low Alcohol Beer

Non-alcoholic beer has been popular internationally for quite some time. More recently, the popularity of these beverages in the US has increased. This category spans beers ranging from <0.5% to about 2.5% ABV. Several methods are used to produce these methods. Not all of them are applicable to the craft beer market but it’s important to understand the different processes used.Vacuum Distillation

Larger breweries more commonly make these beers with some pricey equipment. One of the methods that produces a beer with <0.5% alcohol is vacuum distillation. This is a method in which the beer is heated and the alcohol is removed via the distillation process. This is a great way to reduce a beer with <0.5% alcohol but can produce a beer that has some undesirable off flavors. The heating process can produce off-flavors typical of beer that has been oxidized or with autolysis. Additionally, this equipment can be quite expensive for a craft brewer.Membrane Filtration

A second common method is a membrane filtration of a beer, very similar to the process of making RO water. This membrane specific for this process only allows alcohol, color, and some flavor and aroma compounds through the membrane. What results is alcohol and water is removed from the beer. Water is then returned to the concentrated beer. This methodology could be more approachable for smaller craft breweries as there are more accessible equipment coming to the market. One of the main cons with membrane filtration is that much of the flavor can be stripped along with the alcohol, but ultimately this can result with some of the best tasting results.Additional Methods

Altering the recipe or fermentation of a beer can be a good way to obtain low ABV beers, although achieving <0.5% can be more difficult. The first method would be altering the mash profile. Increasing or decreasing the mash temperature can create less fermentable sugars such as maltose and glucose.

Holding the mash temperature above 158°F will create more dextrins. This approach can produce a low alcohol beer but can also create a “worty” flavor and aroma. Cold mashing is another option in which the temperature of the mash is below starch gelatinization. Blending with water and increasing carbonation are two ways to combat the “worty” flavor.

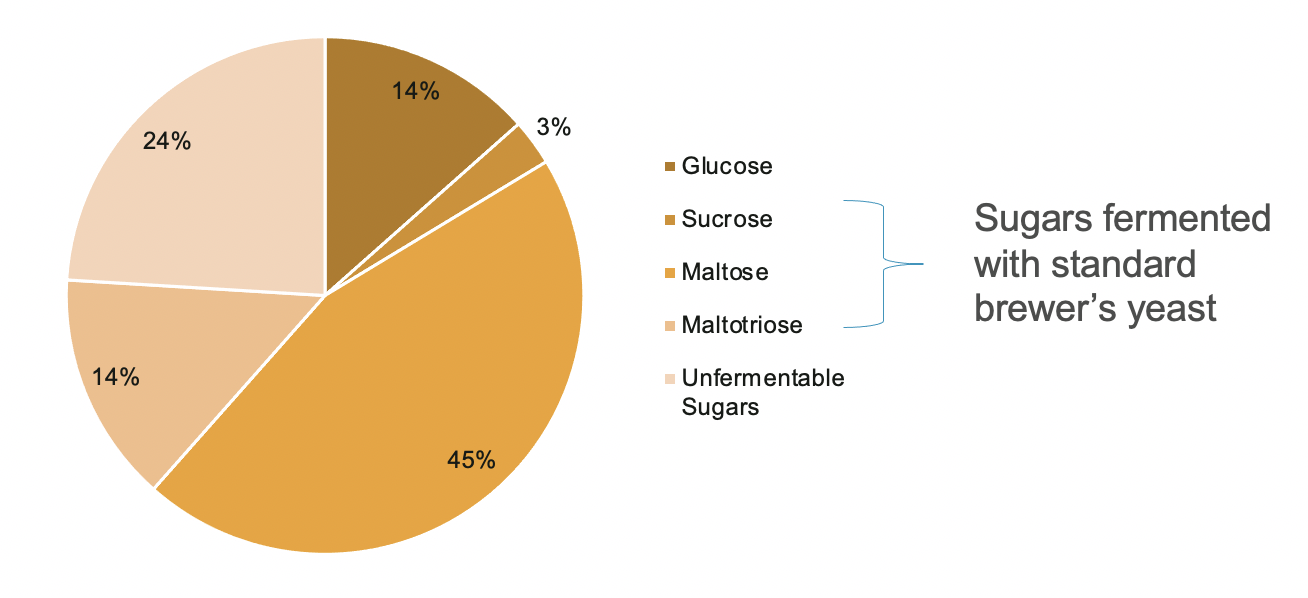

Low Alcohol Yeast Strains

Low alcohol yeasts are a newer topic in the production of low alcohol beer. Many of these are non-Saccharomyces strains that cannot ferment maltose or maltotriose. When using these strains, a beer has to be designed to to have minimal amounts of glucose. All of these strains are non-GMO, although some strains do exist. Examples of low ABV strains that can be used in these types of fermentations:| Strain | Characteristics [1] |

| WLP618 Saccharomycodes ludwigii | Limited maltose and maltotriose consumption. A more neutral strain with some ethyl acetate production |

| WLP603 Torulaspora delbrueckii | Will not ferment maltose and maltotriose. Fruity, ideal for Belgian, saison styles or IPAs |

| WLP686 Zygosaccharomyces lentus | Partial inability to ferment maltose. More neutral but difficult to grow |

These strains can have positive contributions to flavor, such as increased esters, with additionally keeping the fermentation of fermentable sugars low. These will produce beers with an alcohol percentage of around 1-1.5% ABV depending on strain and wort recipe. Using these yeasts will certainly require a certain level of research and development to obtain a delicious, low ABV beer that can compete with products currently on the market.

Pitching rates of these strains can be expected to be lower, as the amount of sugar to be fermented is low. Pitch rates for these beers of lab-grown cultures range from 2-5 million cells/ml.

Non-Alcoholic/Low Alcohol Tech Sheet

References:

1.Capece, Angela & Romaniello, Rossana & Siesto, Gabriella & Romano, Patrizia. (2018). Conventional and Non-Conventional Yeasts in Beer Production. Fermentation. 4. 38. 10.3390/fermentation4020038.

Matched keywords: 1

Best Practices for brewing Low Alcohol/Non-Alcoholic Beers, part 2

A Global Trend

For craft brewers, producing low-ABV beers is an opportunity to extend their portfolio and appeal to a new generation of beer drinkers, which is shifting towards healthier eating and drinking habits, with reduced calories and alcohol consumption. These beers also enable easier compliance with harsher government policies on driving under alcohol influence. This growing global market is expected to reach $23 Billion in 2025 [1].

Read Part 1 Here

Fermentation

Yeast plays a fundamental role in the production of low-ABV beer, particularly how it metabolizes maltose (and maltotriose to a lesser extent), and the selection of a particular yeast species will significantly influence the organoleptic properties and acceptance of the final product.

Some low-ABV beers are produced using the brewer’s yeast Saccharomyces cerevisiae, especially by large breweries. In a lower gravity and fermentability wort, it might be possible to restrict ethanol production using maltotriose-negative brewer’s yeast by controlling the fermentation temperatures and/or reducing the contact time between the yeast and wort. Fermentation at lower temperatures will reduce yeast metabolism and overall ethanol production, making it easier to stop the process when the desired ABV is achieved.

Removing the yeast from the beer before full attenuation is achieved, usually by centrifugation, will also allow the production of low-ABV beers. Residual sweetness and lack of flavor are commonly associated with the final product. Frequently, these beers are further diluted if the final product is a non-alcoholic beer (<0.5 % ABV in most countries).

Some close relatives of brewer’s yeast, namely Saccharomyces cerevisiae var. chevalieri, are very inefficient in maltose metabolism and can produce low-ABV beers. The application of this yeast might require mashing at even higher temperatures (>74 °C) to further reduce the maltose content of the wort.

However, non-conventional yeast like Torulaspora delbrueckii, Saccharomycodes ludwigii, Pichia sp., or Hansenulaspora valbyensis are frequently the main choice for the production of low-ABV beers. These species are unable to ferment maltose or maltotriose to ethanol, but they will produce ethanol from glucose so a low gravity and fermentability wort is required.

Most of such non-conventional yeast has very poor flocculation capacity and the yeast needs to be removed from the beer, usually by centrifugation.

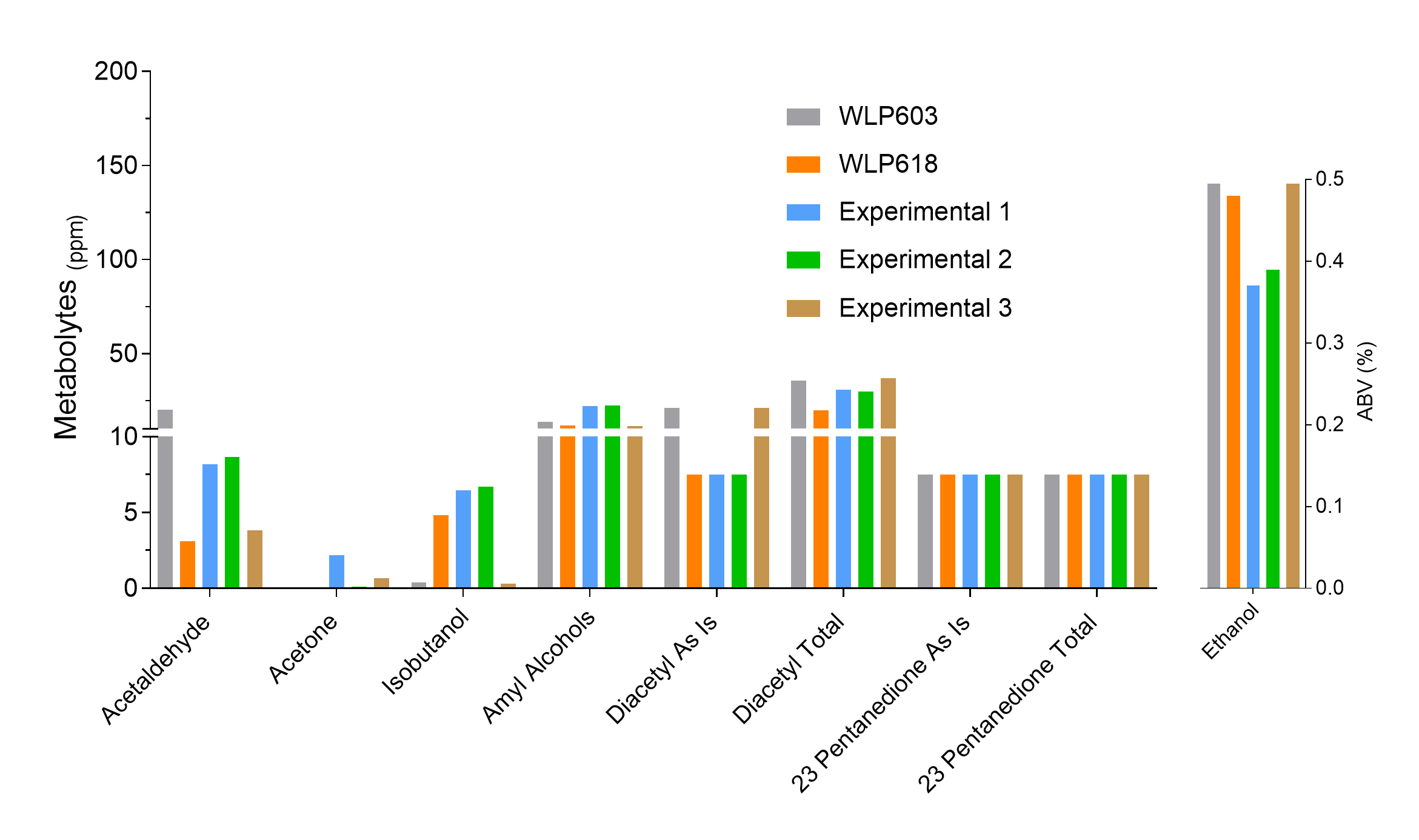

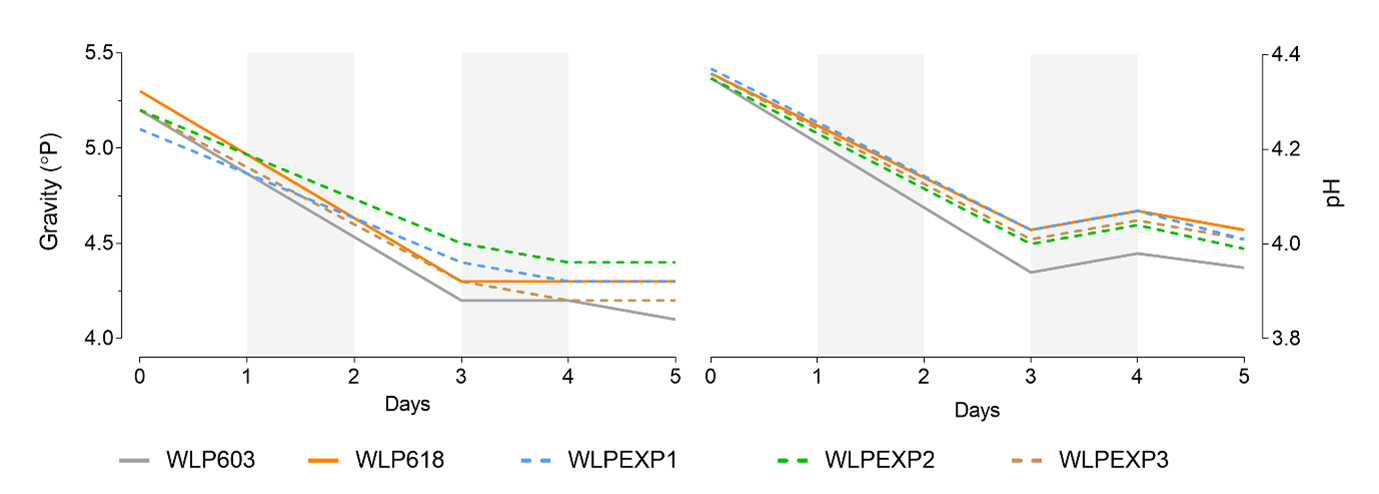

T. delbrueckii strains, like our WLP603 or WLPEXP3, will not ferment maltose and maltotriose. In a low gravity wort (<6 P) at 20 °C, these two strains showed an apparent attenuation of around 20% (Fig. 3). As mentioned above, the initial pH required adjustments with food-grade lactic acid, since the fermentation only made the pH drop less than 0.5 pH units.

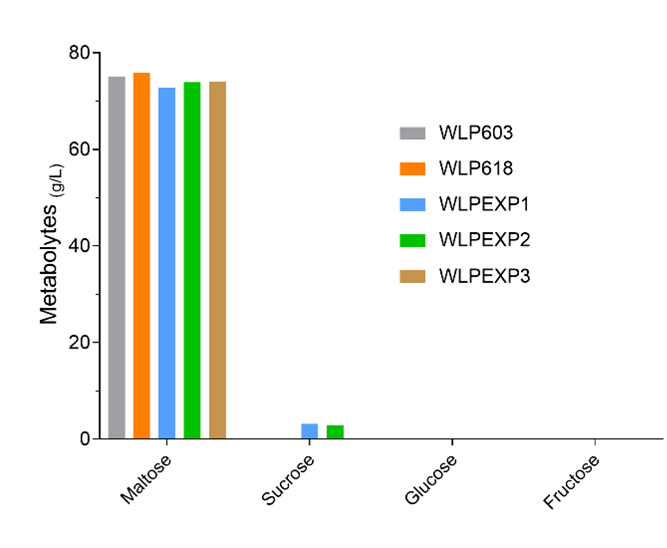

The final beers presented 0.5% ABV (Fig. 4), and some pear and tea notes, with a hint of honey in the background. The beer fermented with WLPEXP3 was cleaner, with more fruit notes present in the WLP603 beer. At 20 °C, some diacetyl was detected (Fig. 4). The fermentation temperature can also be used to control the aromatic profile, with more honey notes at lower temperatures (< 20 °C) and more fruity notes above 20 °C. Sugar analysis of the final beer shows that all the simple sugars were consumed, but over 70 g/L of maltose remains (Fig. 5), emphasizing the potential for spoilage of these types of beers. These T. delbrueckii strains are ideal for low-ABV versions of Belgian and Saison styles or IPAs.

Figure 3. Maltose negative strains in low gravity wort (< 6 P) at 20 °C. All strains pitched at 5 million cells / mL.

Sucrose-negative Pichia sp. strains, like our WLPEXP1 and WLPEXP2, presented an apparent attenuation of 15-16% (Fig. 3) and a maximum ABV of 0.37% (Fig. 4). Sucrose was also detected in the final beer (Fig. 5). These strains produced a slight phenolic aroma, which could potentially be used in some Belgian style beers. Further research is necessary to determine how fermentation conditions, like temperature and pitch rate, can further influence the aroma and flavor profile. Interestingly, several of these strains are known for producing biotransformation enzymes, like β-lyase and β-glucosidase, and could be used to boost hop aromas. Dry hopping could then be used to improve the aroma and flavor of low-ABV beers, but it carries considerable risk as it might introduce microorganisms in the beer. Adding hops after cooling the beer could potentially minimize the contamination risk while extracting hop aroma, but the final product would require some stabilization procedure to avoid spoilage after packaging.

Stabilization

In low-ABV beers, the microbial stability of the beer is at risk as soon as the fermentation is concluded. The relatively high concentration of residual sugars and the low ethanol concentration present in the tank allow for the growth of any microorganism capable of metabolizing maltose. It is generally recommended that the beer is cold crashed as soon as possible after the expected attenuation (usually between 15-20%) is achieved. This will minimize the growth and metabolism of any maltose-utilizing microorganism present. This includes most brewing spoilers but in particular conventional brewing Saccharomyces cerevisiae strain. This is particularly relevant in brewing operations with simultaneous production of regular strength and low ABV beer. Any equipment shared between the two products needs to be thoroughly cleaned before handling low-ABV products.

The shelf-life of the final product is tightly associated with the microbial stability of the beer. Currently, several methods to reduce the microbial load in low ABV are available:

- Tunnel pasteurization (Gold Standard);

- Flash pasteurization;

- Chemical stabilizers (i.e. Sorbates or Sulphur Dioxide);

- Filtration;

- Cold chain.

Chemical stabilizers, like sorbate or sulfur dioxide, are widely used in the soft drink industry and can also be used to inhibit the growth of microorganisms in low-ABV beers. The application of the different stabilizers, and their concentration in the final product, is subject to local legislation.

Beer filtration can also be used to retain yeast and beer-spoiling microorganisms present in the low ABV beers. Typically, a fine filter is used to reduce the microbial load, followed by a final beer membrane filter (0.65 to 0.45 um microbially rated membrane cartridges). Such filters capture most beer-relevant microorganisms (Table 1), but are not considered sterilizing according to FDA rules.

| Microorganism | Species Name | Approximate dimensions |

| Yeast | Saccharomyces sp. | 3 – 5 µm, oval |

| Yeast | Brettanomyces sp. | 5 – 10 µm, oval to pseudo-hyphae |

| Bacteria | Pediococcus sp. | 0.6 µm x 2 µm, short rods |

| Bacteria | Lactobacillus sp. | 0.5 µm x 2 µm, long rods |

Thus, final beer membrane cartridges provide a reduction of microorganisms and not necessarily a sterile product. Such filters often express microbial reduction efficiency as Log Reduction Value (LRV) or titer reduction, indicating the removal of a number of microbes per cm2 of filter area. Using a final beer filter rated LRV 6, a brewer can expect up to 1 colony forming unit per 1 000 000 microorganisms in the beer sample. Similar to the flash pasteurization technology, this approach carries the risk of contamination during packaging.

Finally, the simplest method to control the microbial activity in low-ABV beers is keeping the cold chain at all moments, from when the beer finishes fermentation to the final sales point. This approach carries the highest risk, as microorganisms are always present in the beverage and its activity is kept low only by the very low storage temperatures (2-4 °C). The final beer requires centrifugation to reduce the microbial load to a minimum, and thoroughly cleaning all equipment touching the beer is of special importance. Ensuring the cold chain during distribution and at the point of sale is another challenge.

Special consideration is required when offering low-ABV draft beers, as these present a higher risk of contamination from the serving lines. Any microorganism present in the serving system, from a previous beer or poorly cleaned lines, will start fermenting the residual sugars in the low-ABV beer and eventually spoil it.

Conclusion

Overall, by applying biological methods in the production of low-ABV beers, a brewer is trying to restrict the production of ethanol while maximizing flavor and aroma production. The stabilization methods will ensure the final customer receives a stable product that looks and tastes as the brewer intended. Ultimately, the choice of mashing conditions, microorganisms, and stabilization technology will control the sensory attributes of the product and significantly influence public acceptance, so trials are necessary to find the right conditions for each beer.

At White Labs, we strive to provide solutions to help our partners produce flavorful low-ABV products. Our R&D department is continuously focused on isolating and characterizing new species and strains, and we will keep releasing new products that can contribute to the low-cost production of great-tasting low ABV beers.

References

1. B Wire. Global Non-Alcoholic Beer Market Report 2021: Market is Expected to Reach $23.27 Billion in 2025 at a CAGR of 8.7% - Forecast to 2030 - ResearchAndMarkets.com. 2022 2022/04/04]; Available from: https://www.businesswire.com/news/home/20220104005772/en/Global-Non-Alcoholic-Beer-Market-Report-2021-Market-is-Expected-to-Reach-23.27-Billion-in-2025-at-a-CAGR-of-8.7---Forecast-to-2030---ResearchAndMarkets.com.

Matched keywords: 1

Yeast & Bacteria Bank

Yeast & Bacteria Bank

Enzymes & Nutrients

Enzymes & Nutrients

Lab Services

Lab Services

Education

Education

Merchandise

Merchandise