Compound Spotlight: Diacetyl

Category: Usually undesirable

Aroma: Butter, butterscotch

Threshold (in beer): 50-100ppb

Fig. 1 Chemical structure of Diacetyl

Fig. 1 Chemical structure of Diacetyl

Introduction to Diacetyl

Diacetyl is a chemical compound produced by brewer’s yeast which can be reminiscent of butter or buttered popcorn. While a few styles (e.g. some English ales and European lagers) have low levels of diacetyl, it is generally considered undesirable at any perceived level.

So if we don’t want it in our beer, why is it there and how do we manage it?

Factors that influence the diacetyl levels in beer are yeast strain selection, fermentation temperature, aeration, and maturation time. Let’s look at how diacetyl is formed and how the levels vary during fermentation and maturation.

What is Diacetyl and How is it Formed?

Diacetyl belongs to a chemical group called ketones. It is a vicinal diketone (VDK) along with 2,3-pentanedione (honey-like aroma). While these compounds are common in all beers, it’s important to understand their role in yeast metabolism.

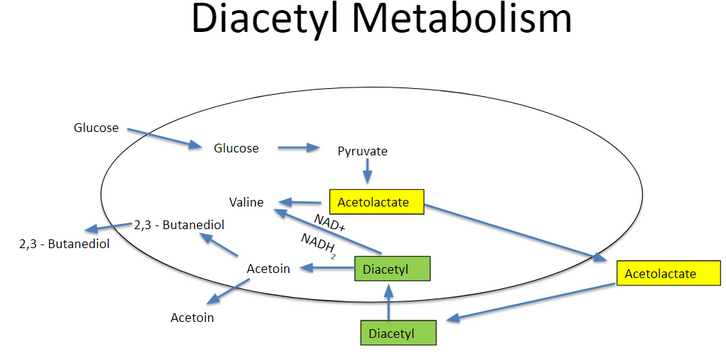

Soon after yeast is pitched into wort it enters a phase of very rapid growth called the exponential growth phase. During this phase, yeast performs critical metabolic functions including the production of amino acids, specifically in the case of diacetyl production, valine.

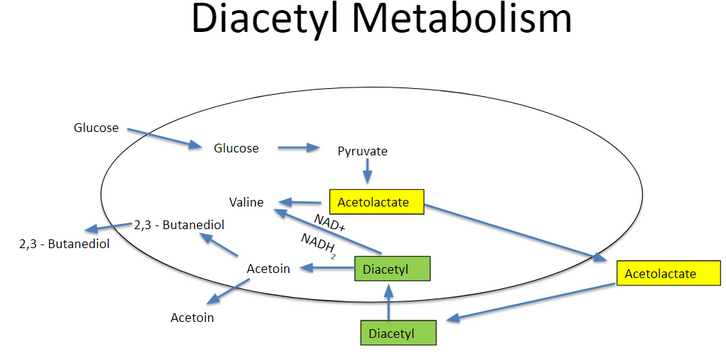

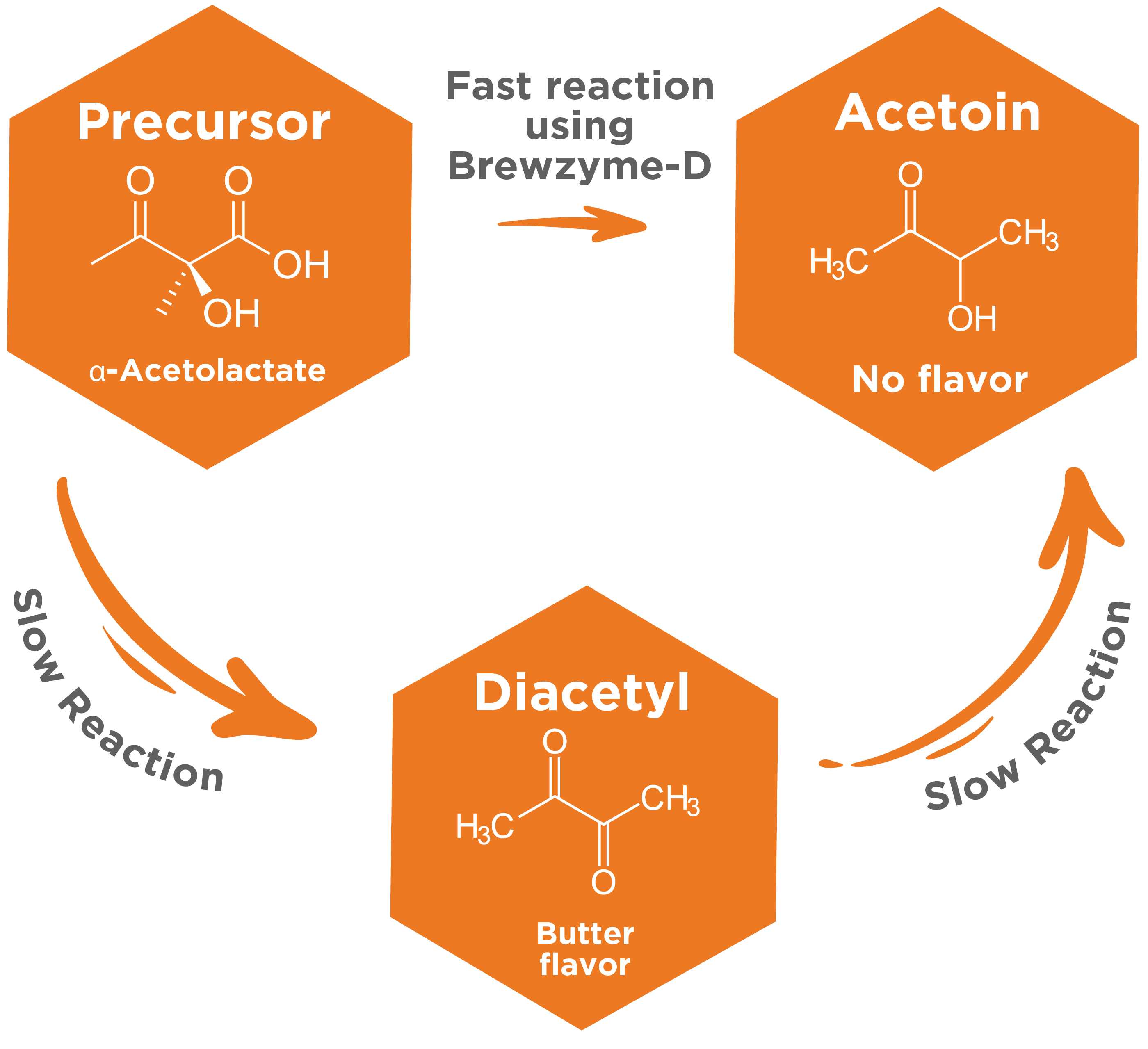

During the process of producing valine, the yeast cell produces a compound known as ɑ-acetolactate(Fig 2). Not all of the ɑ-acetolactate produced eventually becomes valine, some will leak out of the cell and into the beer.

Ok, keep following, we’re almost to the diacetyl part.

Outside the cell, ɑ-acetolactate is then chemically (not enzymatically) converted to diacetyl in the beer causing the unwanted flavor of butter/butter-popcorn. The chemical reaction is caused by oxidation, which will speed up with an increase in temperature.

Diacetyl production can also be affected by insufficient nutrients. If FAN levels are low, the yeast will need to adjust their metabolism to create more amino acids, specifically in this case, the amino acid valine. The more valine that is produced, the more ɑ-acetolactate is required, and subsequently, the more diacetyl is made.

Fig 2. Diacetyl Metabolism Pathway

Fig 2. Diacetyl Metabolism Pathway

Controlling Diacetyl

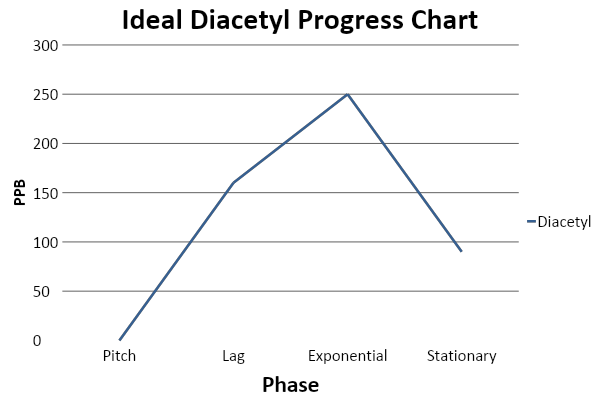

As fermentation slows, yeast enters the stationary/maturation phase (Fig 3). During this phase, diacetyl can reduce with proper maturation.

Diacetyl will re-enter the cell and will be converted into acetoin and subsequently into 2,3-butanediol (Fig 2). Both acetoin and 2,3-butanediol are generally considered not to have an effect on sensory due to the low levels that are produced and their high sensory threshold.

Fig 3.Diacetyl levels in fermentation

Give it a Rest

To help ensure the reabsorption of diacetyl into the yeast cell, a diacetyl rest can be performed. A diacetyl rest is when the fermentation temperature is raised a couple of degrees when the gravity is a few degrees Plato from terminal. Diacetyl rests can be performed in either ale or lager ferments but are recommended especially for lagers or cooler fermentation profiles.

An example of a diacetyl rest:

Pitch at 50°F/10°C

3° Plato from terminal gravity raise temperature to 65°F/18°C

To expedite and relieve longer tank maturations times such as a Diacetyl Rest. Add Brewzyme-D at the beginning of fermentation. To eliminate the risk of diacetyl formation in your beer with Brewzyme D. Adding Brewzyme D with your yeast pitch results in the decarboxylation of alpha acetolactate to acetoin. Breaking down the precursor to diacetyl during fermentation prevents diacetyl from forming, reducing maturation time and improving overall beer quality.

Forced Diacetyl Test

An easy way to test for total diacetyl that requires minimal laboratory equipment is by performing a forced diacetyl test.

To do this, a beer sample is collected then centrifuged and decanted to remove most yeast in suspension from the beer. The clarified beer is then put in a 140°F/60°C water bath for 15-30 minutes. The heat from the water bath helps convert the ɑ-acetolactate into diacetyl. If ɑ-acetolactate or diacetyl is present, it will be perceivable in the aroma.

VDK by Gas Chromatograph

For quantitative results of VDKs we suggest analyzing samples via gas chromatography.

Here are two of the most popular laboratory analysis tests White Labs offers:

Diacetyl As-Is Testing (diacetyl only)

Total Diacetyl Testing (the combined amount of diacetyl and ɑ-acetolactate)

Did you know?! We test all White Labs Brewing Company beers using our lab for Diacetyl, As is and Total levels!

Keeping Butter Flavor to Your Popcorn

Diacetyl is a natural byproduct of fermentation, but there are many ways to control this compound. Healthy yeast, proper maturation time and temperature (as well as sanitary brewing practices!) are great ways of ensuring low levels of diacetyl in your finished beer!

Yeast & Bacteria Bank

Yeast & Bacteria Bank

Enzymes & Nutrients

Enzymes & Nutrients

Lab Services

Lab Services

Education

Education

Merchandise

Merchandise