Transatlantic Berliner Blend

WLP4645Matched keywords: 2

Belgian Sour Mix 1

WLP655Pitch Rate Calculator

Matched keywords: 1

Flemish Ale Blend

WLP665Pitch Rate Calculator

Matched keywords: 1

American Farmhouse Blend

WLP670Pitch Rate Calculator

Matched keywords: 1

Kombucha Cultures

WLP600White Labs Kombucha Cultures are free of food pathogens and have been genetically identified to know specifically what yeast and bacteria are involved in the fermentation of kombucha. A complex combination of yeast and bacteria perfect for low alcohol production and medium acetic acid flavor.

A quick starter liquid is consisting of different bacteria and unique yeast strains!

Bacteria:

Bacillus sp. licheniformis (99%)

Bacillus sp. pumillus/aerophilus/safensis/altitudinis (99%)*

Acetobacter tropicalis (99%)

Bacillus sp. aerophilus (96%)

Bacillus sp. aryabhattai (98%)

Gluconacetobacter saccharivorans (99%)

Micrococcus sp. (98%)

Gluconacetobacter rhaeticus (98%)

Paenibacillus taichungensis (97%)

Bacillus sp. subtilis (99%)

Yeast:

Brettanomyces bruxellensis (99%)

Saccharomyces cerevisiae (92%)

Zygosaccharomyces sp. (97%)

Candida sp. (97%)

*Multiple organisms are listed as they are unable to be differentiated from their 16s ribosomal DNA sequence.

**This is a non-pathogenic species that is commonly found in probiotics.

WLP600-HB

This SCOBY has medium acetic acid production and low alcohol production based on our recipe. The SCOBY diameter is 2.92 inches.

WLP600-Pro

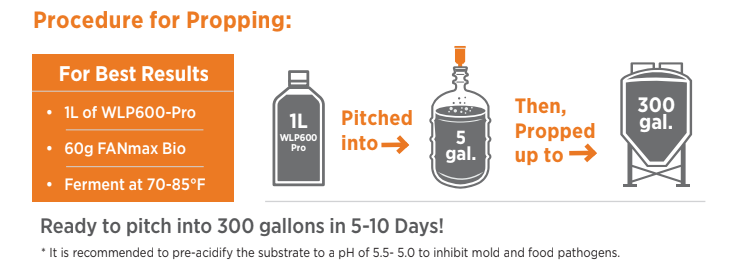

Available in liquid 1L Nalgene bottles, this product can be ordered in quantities for a whole batch or as a middle step-up propagation.

Follow our quick and easy recipe to scale from 5 to 300 gallons

Steps for Propagation

equipment properly.

2. Once cooled to below 90 degrees Fahrenheit, add 1 liter of WLP600-Pro Commercial

Kombucha Starter culture.

3. Take the pH of the culture. If pH is >4.6, add vinegar to adjust the pH.

4. Check for activity over the course of 5-10 days at 70-85 ̊F. The warmer the temperature the

faster the culture will build. Take pH readings to ensure the culture is active. A thin layer of

SCOBY may or may not form. Culture may look very active. Typical final pH ranges between

3.2 to 3.6.

5. Inoculate up to 300 gallons of prop wort into your kombucha recipe with this starter culture.

FANMax BIo® (Yeast nutrient) is not required.

Matched keywords: 1

Dark Belgian Cask Yeast Blend

WLP4653Matched keywords: 1

Mélange Yeast Blend

WLP4633Matched keywords: 1

The Yeast Bay House Sour Blend

WLP4684TYB House Sour Blend is a complex culture developed over 10+ years of isolation work. Each lot consists largely of rotating base strains along with new isolates of Saccharomyces, Brettanomyces, Lactobacillus, Pediococcus, and other wild yeasts.

Contains STA1+ components.

Matched keywords: 1

Making Homebrew Kombucha with White Labs SCOBY

What is kombucha?

Kombucha is a popular fermented drink traditionally made of sugar, black tea, and a SCOBY.What is a SCOBY?

A SCOBY is an acronym for Symbiotic Culture of Bacteria and Yeast. These SCOBYs consist of microorganisms that differ greatly depending on the environment. Typically the SCOBY or “mother” are transferred batch to batch, each time you make kombucha. The organisms present produce cellulose during the fermentation process and create a biofilm, which creates a thick, gelatinous pad at the top of the fermentation vessel.What organisms are in White Lab’s SCOBY?

In our WLP600 SCOBY we have identified organisms through multiple methods including plating on microbial media, DNA sequencing, and some more advanced genetic techniques. Some of the species we’ve identified are below. The percent (%) confidence is listed for each organism based on the analysis. Each SCOBY is tested for pathogenic food spoilage organisms before packaging.Bacteria:

- Bacillus sp.

- Acetobacter tropicalis (99%)

- Gluconacetobacter saccharivorans (99%)

- Micrococcus sp. (98%)

- Gluconacetobacter rhaeticus (98%)

- Paenibacillus taichungensis (97%)

- Brettanomyces bruxellensis (99%)

- Saccharomyces cerevisiae (92%)

- Zygosaccharomyces sp. (97%)

- Candida sp. (97%)

How do I keep my SCOBY healthy?

It’s important to keep SCOBYs free of mold and drying out. SCOBYs are quite hardy and can endure changes in temperatures and conditions quite easily.Watch your temperatures. If the SCOBY becomes too warm and liquid evaporates, it could dry out.

Room temperature is fine for short term storage (< 2 months). For long-term storage we recommend they be refrigerated. If the fermentation is too cold, it will take longer for the fermentation.

Keeping the top of your SCOBY wet will help reduce the chances of mold developing. Additionally, keeping the fermentation away from air drafts (windows, doors, air vents) will also help reduce this.

How do I control the alcohol in my fermentation?

The main ingredient that has to be considered is sugar. Yeast converts sugar into alcohol and this is where the alcohol is coming from. It is difficult to control the yeast population in your SCOBY so it is much easier to control the sugar content. Check out our recipe below for a good starting place for a <0.5% ABV kombucha.What do I need to make a hard/alcoholic kombucha?

Making a hard kombucha is relatively similar except you’ll need more sugar, yeast, and nutrients. The nutrients in tea aren’t typically enough for a 4-7% alcoholic fermentation and we recommend adding additional nutrients, such as our FANMAXBio. Using a brewing recipe program, such as Beersmith, can help you formulate recipes that will help you achieve your desired ABV.What lab analyses does White Labs offer?

The most important lab analysis we offer is alcohol analysis since it is regulated by the FDA and TTB. We offer two types of analysis, Alcohol by volume analysis by Gas Chromatography and analysis by Anton Paar Alcolyzer.Here is a full catalog of other kombucha based analyses we offer. Click Here

Recipe:

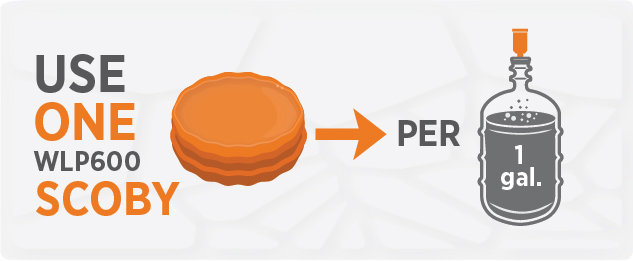

This recipe has been developed for making 1 gallon of non-alcoholic kombucha with our SCOBY. Our SCOBY contains a starter liquid that helps reduce the pH and kick start the fermentation.Ingredients needed:

14 cups water

1 cup sugar

8 tea bags

2 cups starter tea (or store-bought kombucha)

1 WLP600 SCOBY per fermentation container

Materials needed:

Pot to boil water

1-gallon bucket, or jar for the fermentation container

Tea towel or tightly woven cloth

1-gallon growler or food-grade bucket- Clean and sanitize before use

Procedure

1. Measure out 14 cups water and bring it to a boil in a large pot. Remove from heat, add 1 cup sugar and stir until dissolved. Place 8 tea bags into the hot water and steep for 30 minutes.

2. Remove tea bags and pour the mixture into the fermentation container.

3. When tea is at room temperature, place the SCOBY into the tea with clean hands, Add 2 cups of stater tea then cover the container with a tea towel or any tightly woven cloth. Secure in place with a rubber band.

4. Keep the fermentation container at room temperature away from sunlight (to avoid evaporation). Ferment for 7 to 14 days and check periodically.

5. After 7 days start to taste the kombucha daily until it obtains the flavor and acidity that is desired.

6. Once kombucha is ready, remove the SCOBY and store it at room temperature in roughly 1 cup of the kombucha that was just brewed using a breathable container. Refill the liquid with sweet tea as it begins to absorb and evaporate liquid.

7. Transfer kombucha into the growler, and add any herbs or fruit for flavoring as desired.

8. Refrigerate the kombucha to stop the fermentation.

Matched keywords: 1

Best Practices for brewing Low Alcohol/Non-Alcoholic Beers, part 2

A Global Trend

For craft brewers, producing low-ABV beers is an opportunity to extend their portfolio and appeal to a new generation of beer drinkers, which is shifting towards healthier eating and drinking habits, with reduced calories and alcohol consumption. These beers also enable easier compliance with harsher government policies on driving under alcohol influence. This growing global market is expected to reach $23 Billion in 2025 [1].

Read Part 1 Here

Fermentation

Yeast plays a fundamental role in the production of low-ABV beer, particularly how it metabolizes maltose (and maltotriose to a lesser extent), and the selection of a particular yeast species will significantly influence the organoleptic properties and acceptance of the final product.

Some low-ABV beers are produced using the brewer’s yeast Saccharomyces cerevisiae, especially by large breweries. In a lower gravity and fermentability wort, it might be possible to restrict ethanol production using maltotriose-negative brewer’s yeast by controlling the fermentation temperatures and/or reducing the contact time between the yeast and wort. Fermentation at lower temperatures will reduce yeast metabolism and overall ethanol production, making it easier to stop the process when the desired ABV is achieved.

Removing the yeast from the beer before full attenuation is achieved, usually by centrifugation, will also allow the production of low-ABV beers. Residual sweetness and lack of flavor are commonly associated with the final product. Frequently, these beers are further diluted if the final product is a non-alcoholic beer (<0.5 % ABV in most countries).

Some close relatives of brewer’s yeast, namely Saccharomyces cerevisiae var. chevalieri, are very inefficient in maltose metabolism and can produce low-ABV beers. The application of this yeast might require mashing at even higher temperatures (>74 °C) to further reduce the maltose content of the wort.

However, non-conventional yeast like Torulaspora delbrueckii, Saccharomycodes ludwigii, Pichia sp., or Hansenulaspora valbyensis are frequently the main choice for the production of low-ABV beers. These species are unable to ferment maltose or maltotriose to ethanol, but they will produce ethanol from glucose so a low gravity and fermentability wort is required.

Most of such non-conventional yeast has very poor flocculation capacity and the yeast needs to be removed from the beer, usually by centrifugation.

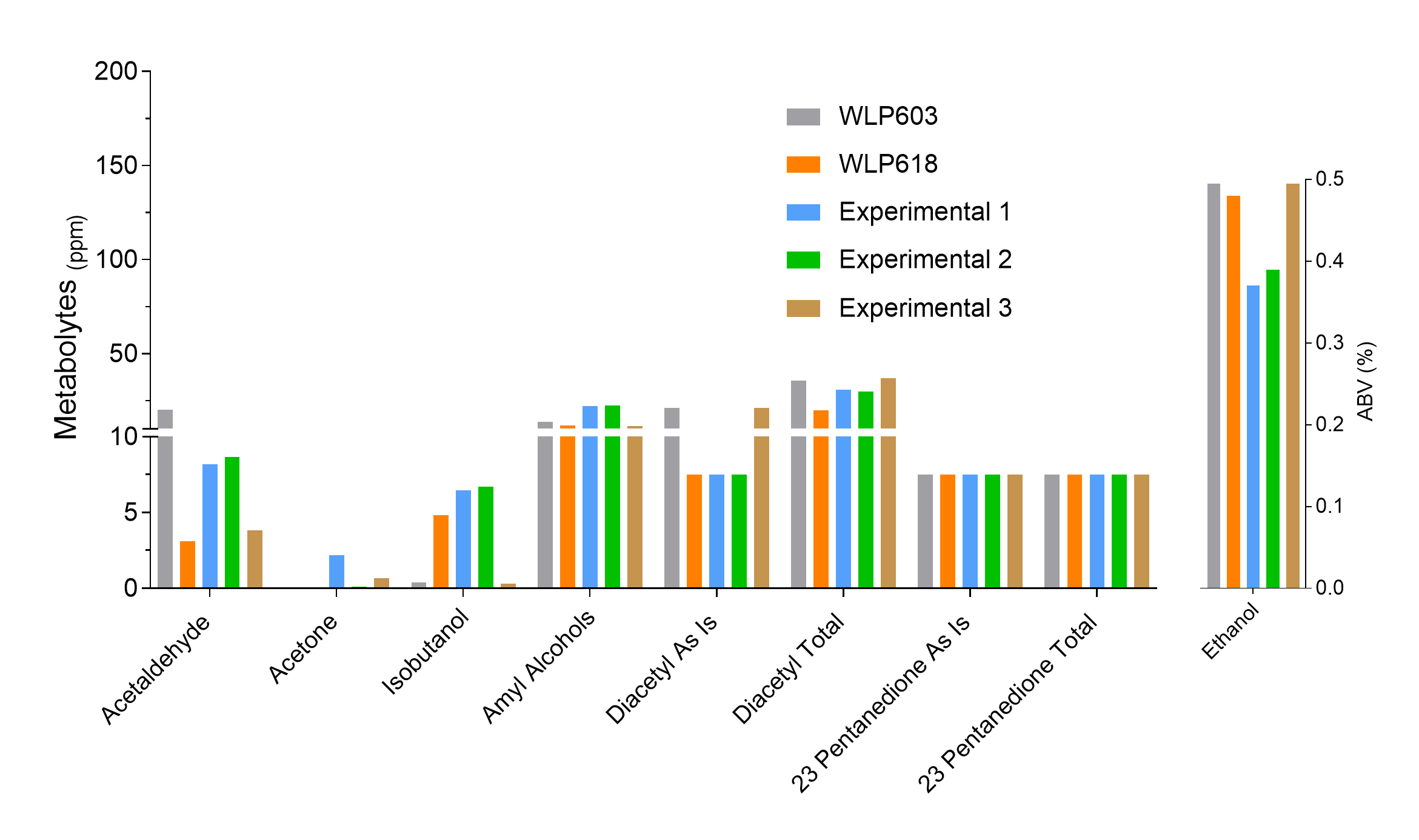

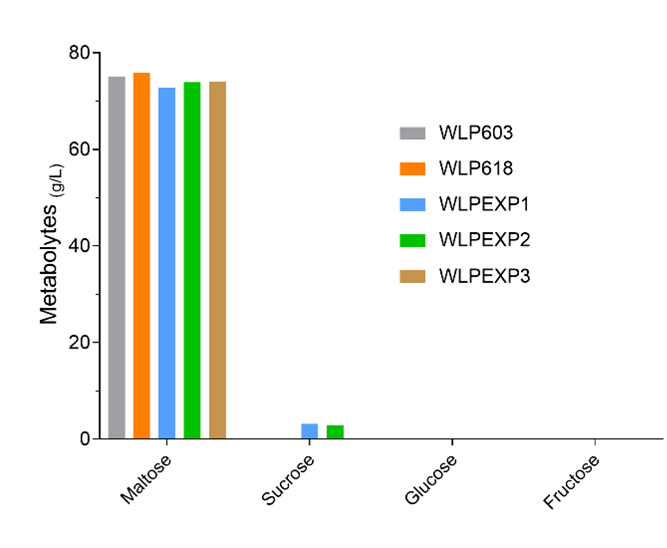

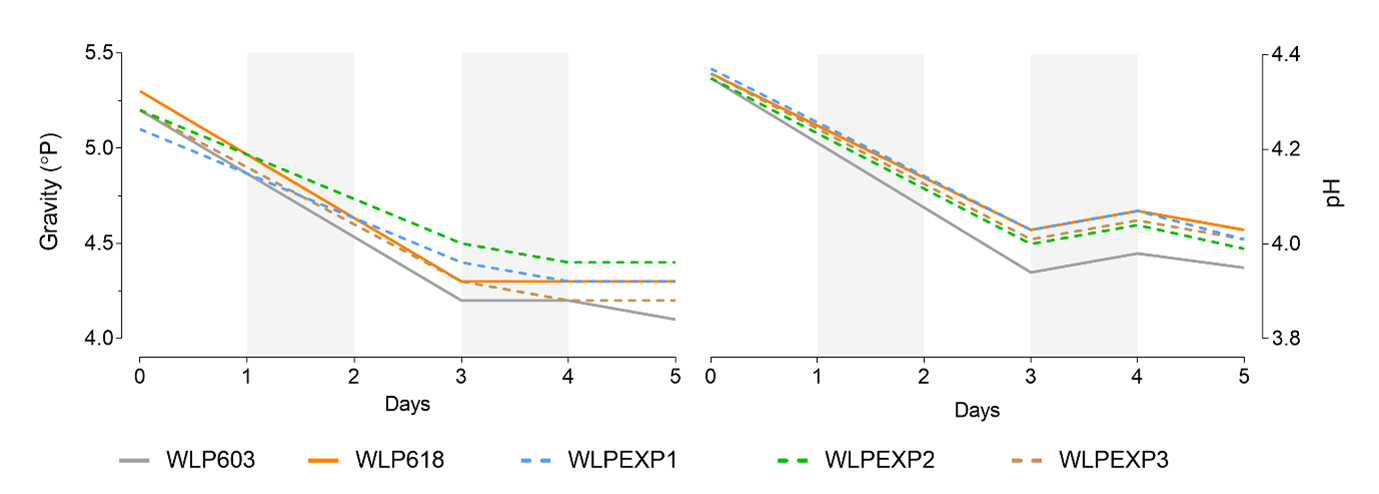

T. delbrueckii strains, like our WLP603 or WLPEXP3, will not ferment maltose and maltotriose. In a low gravity wort (<6 P) at 20 °C, these two strains showed an apparent attenuation of around 20% (Fig. 3). As mentioned above, the initial pH required adjustments with food-grade lactic acid, since the fermentation only made the pH drop less than 0.5 pH units.

The final beers presented 0.5% ABV (Fig. 4), and some pear and tea notes, with a hint of honey in the background. The beer fermented with WLPEXP3 was cleaner, with more fruit notes present in the WLP603 beer. At 20 °C, some diacetyl was detected (Fig. 4). The fermentation temperature can also be used to control the aromatic profile, with more honey notes at lower temperatures (< 20 °C) and more fruity notes above 20 °C. Sugar analysis of the final beer shows that all the simple sugars were consumed, but over 70 g/L of maltose remains (Fig. 5), emphasizing the potential for spoilage of these types of beers. These T. delbrueckii strains are ideal for low-ABV versions of Belgian and Saison styles or IPAs.

Figure 3. Maltose negative strains in low gravity wort (< 6 P) at 20 °C. All strains pitched at 5 million cells / mL.

Sucrose-negative Pichia sp. strains, like our WLPEXP1 and WLPEXP2, presented an apparent attenuation of 15-16% (Fig. 3) and a maximum ABV of 0.37% (Fig. 4). Sucrose was also detected in the final beer (Fig. 5). These strains produced a slight phenolic aroma, which could potentially be used in some Belgian style beers. Further research is necessary to determine how fermentation conditions, like temperature and pitch rate, can further influence the aroma and flavor profile. Interestingly, several of these strains are known for producing biotransformation enzymes, like β-lyase and β-glucosidase, and could be used to boost hop aromas. Dry hopping could then be used to improve the aroma and flavor of low-ABV beers, but it carries considerable risk as it might introduce microorganisms in the beer. Adding hops after cooling the beer could potentially minimize the contamination risk while extracting hop aroma, but the final product would require some stabilization procedure to avoid spoilage after packaging.

Stabilization

In low-ABV beers, the microbial stability of the beer is at risk as soon as the fermentation is concluded. The relatively high concentration of residual sugars and the low ethanol concentration present in the tank allow for the growth of any microorganism capable of metabolizing maltose. It is generally recommended that the beer is cold crashed as soon as possible after the expected attenuation (usually between 15-20%) is achieved. This will minimize the growth and metabolism of any maltose-utilizing microorganism present. This includes most brewing spoilers but in particular conventional brewing Saccharomyces cerevisiae strain. This is particularly relevant in brewing operations with simultaneous production of regular strength and low ABV beer. Any equipment shared between the two products needs to be thoroughly cleaned before handling low-ABV products.

The shelf-life of the final product is tightly associated with the microbial stability of the beer. Currently, several methods to reduce the microbial load in low ABV are available:

- Tunnel pasteurization (Gold Standard);

- Flash pasteurization;

- Chemical stabilizers (i.e. Sorbates or Sulphur Dioxide);

- Filtration;

- Cold chain.

Chemical stabilizers, like sorbate or sulfur dioxide, are widely used in the soft drink industry and can also be used to inhibit the growth of microorganisms in low-ABV beers. The application of the different stabilizers, and their concentration in the final product, is subject to local legislation.

Beer filtration can also be used to retain yeast and beer-spoiling microorganisms present in the low ABV beers. Typically, a fine filter is used to reduce the microbial load, followed by a final beer membrane filter (0.65 to 0.45 um microbially rated membrane cartridges). Such filters capture most beer-relevant microorganisms (Table 1), but are not considered sterilizing according to FDA rules.

| Microorganism | Species Name | Approximate dimensions |

| Yeast | Saccharomyces sp. | 3 – 5 µm, oval |

| Yeast | Brettanomyces sp. | 5 – 10 µm, oval to pseudo-hyphae |

| Bacteria | Pediococcus sp. | 0.6 µm x 2 µm, short rods |

| Bacteria | Lactobacillus sp. | 0.5 µm x 2 µm, long rods |

Thus, final beer membrane cartridges provide a reduction of microorganisms and not necessarily a sterile product. Such filters often express microbial reduction efficiency as Log Reduction Value (LRV) or titer reduction, indicating the removal of a number of microbes per cm2 of filter area. Using a final beer filter rated LRV 6, a brewer can expect up to 1 colony forming unit per 1 000 000 microorganisms in the beer sample. Similar to the flash pasteurization technology, this approach carries the risk of contamination during packaging.

Finally, the simplest method to control the microbial activity in low-ABV beers is keeping the cold chain at all moments, from when the beer finishes fermentation to the final sales point. This approach carries the highest risk, as microorganisms are always present in the beverage and its activity is kept low only by the very low storage temperatures (2-4 °C). The final beer requires centrifugation to reduce the microbial load to a minimum, and thoroughly cleaning all equipment touching the beer is of special importance. Ensuring the cold chain during distribution and at the point of sale is another challenge.

Special consideration is required when offering low-ABV draft beers, as these present a higher risk of contamination from the serving lines. Any microorganism present in the serving system, from a previous beer or poorly cleaned lines, will start fermenting the residual sugars in the low-ABV beer and eventually spoil it.

Conclusion

Overall, by applying biological methods in the production of low-ABV beers, a brewer is trying to restrict the production of ethanol while maximizing flavor and aroma production. The stabilization methods will ensure the final customer receives a stable product that looks and tastes as the brewer intended. Ultimately, the choice of mashing conditions, microorganisms, and stabilization technology will control the sensory attributes of the product and significantly influence public acceptance, so trials are necessary to find the right conditions for each beer.

At White Labs, we strive to provide solutions to help our partners produce flavorful low-ABV products. Our R&D department is continuously focused on isolating and characterizing new species and strains, and we will keep releasing new products that can contribute to the low-cost production of great-tasting low ABV beers.

References

1. B Wire. Global Non-Alcoholic Beer Market Report 2021: Market is Expected to Reach $23.27 Billion in 2025 at a CAGR of 8.7% - Forecast to 2030 - ResearchAndMarkets.com. 2022 2022/04/04]; Available from: https://www.businesswire.com/news/home/20220104005772/en/Global-Non-Alcoholic-Beer-Market-Report-2021-Market-is-Expected-to-Reach-23.27-Billion-in-2025-at-a-CAGR-of-8.7---Forecast-to-2030---ResearchAndMarkets.com.

Matched keywords: 1

Biotransformation: a legitimately exciting beer trend

During fermentation, biotransformation occurs when some yeast-derived enzymes convert odorless and flavorless hop precursors into desirable flavors and aromas (Fig.1), making it particularly relevant for popular styles like juicy and fruity IPAs.

Research on this subject is constantly emerging, with much of the knowledge borrowed from the wine industry. This complex process involves three main reactions: i) Terpene alcohol release, ii) conversion, and iii) Thiol release.

Terpene Release

Thiol Release

Not all yeasts are created alike, and only yeast strains that present a functional version of the IRC7 gene can perform this reaction. At White Labs, we screened our entire yeast collection for the presence of this enzyme activity. We developed a blended culture of several high-activity strains, WLP077 Tropicale Yeast Blend, to create the perfect balance of tropical aroma for a juicy, hazy IPA!

Check out WLP077 Tropicale Yeast Blend

Choosing the Right Hops

Matched keywords: 1

Yeast & Bacteria Bank

Yeast & Bacteria Bank

Enzymes & Nutrients

Enzymes & Nutrients

Lab Services

Lab Services

Education

Education

Merchandise

Merchandise