Backed By Science

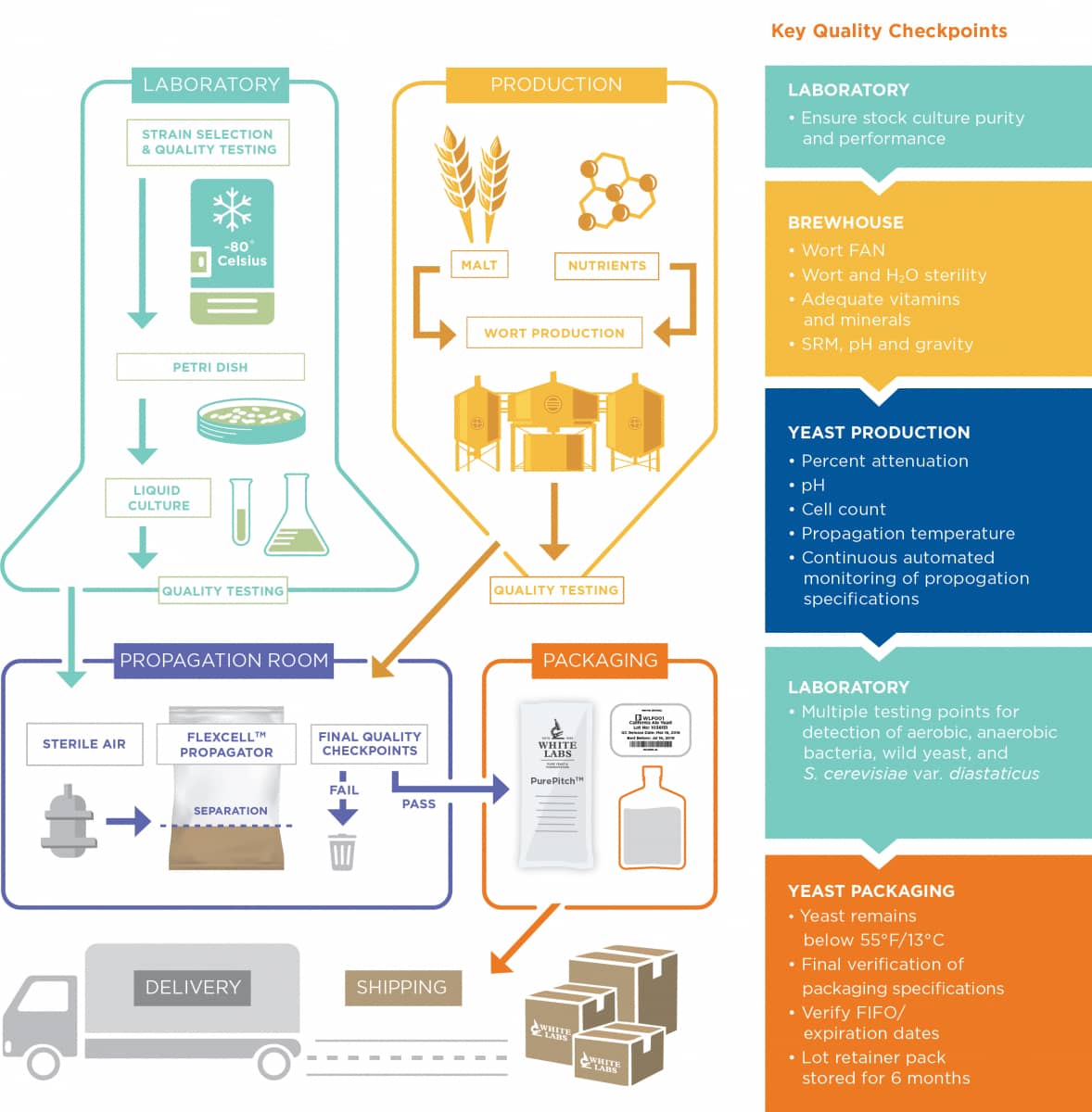

Our 21-day process and uncompromising quality specifications ensure the highest quality and most viable yeast for reliable and consistent fermentations.

We’re Serious About Science

Science is important to us. That’s why we invest considerable resources into our quality control and we are pioneers in yeast technology, providing you with the best and most reliable fermentation cultures. Our exclusive 21-day process produces the most viable yeast and our packaging technology, including our improved proprietary film, delivers superior yeast health and longer shelf life. We take pride in these advancements and push ourselves to continue leading the charge when it comes to yeast (and alternative cultures).Uncompromising Quality

From cryogenic (-80C) storage through the fulfillment of yeast from our cold storage warehouse, every batch goes through 38 Quality Checkpoints. We stand by the recognized industry-standard microbiological testing methods (ASBC and AOAC), along with proprietary qPCR methods developed with Invisible Sentinel for the most dependable and sensitive limit of detection. These rigorous standards provide you with quality you can trust and foolproof fermentations you can count on every time.21-Day Propagation

Over the decades of our research and development, we have optimized our propagation process, resulting in yeast big plump cells full of nutrients and healthy cell membranes great for sustained viability and reuse.

FlexCell Technology

Our patented FlexCell process grows yeast with minimal exposure to the environment, ensuring quality and purity in every package. The improved proprietary packaging material allows for one-way off-gassing to reduce product inflation and deliver better yeast health and longer shelf life.

White Labs is demonstrating our commitment to sustainability by reducing water, electricity, and cleaners used to sanitize traditional propagation vessels during the transfer process and reducing our overall use of rigid plastic packaging material. The PurePitch® package is more recyclable and more breathable, reducing the chance of gas buildup and maintaining a favorable environment for the yeast. The FlexCell™ process and PurePitch® package deliver the purity and high-quality yeast that you expect from White Labs.

“The PurePitch® package is more recyclable and more breathable, reducing the chance of gas buildup and maintaining a favorable environment for the yeast.”

Quality Control with over 38 Quality Checkpoints

We pride ourselves in verified quality control testing, including standard industry-wide microbiological testing (selective media plating) AND proprietary qPCR methods (developed with Invisible Sentinel) for the most sensitive limit of detection.We monitor checkpoints on every batch, such as:

- Culture purity at multiple growth stages

- Gravity and attenuation

- Precise cell counts and viability

- Presence of STA1 (Diastatic) gene in our strains

Groundbreaking qPCR Microbial Contaminants Panel

A proprietary multiplexed detection kit developed by Invisible Sentinel and White Labs

Utilizing qPCR technology, these novel detection kits can target a range of brewery contaminants at once, providing faster results, greater sensitivity, and a higher level of accuracy;

Wild yeast, including STA1, per 40 million yeast cells

Aerobic bacteria per 40 million yeast cells

Anaerobic bacteria per 140 million yeast cells

Visit here to view the QC report for your lot of yeast.

How Does White Labs Ship Yeast?

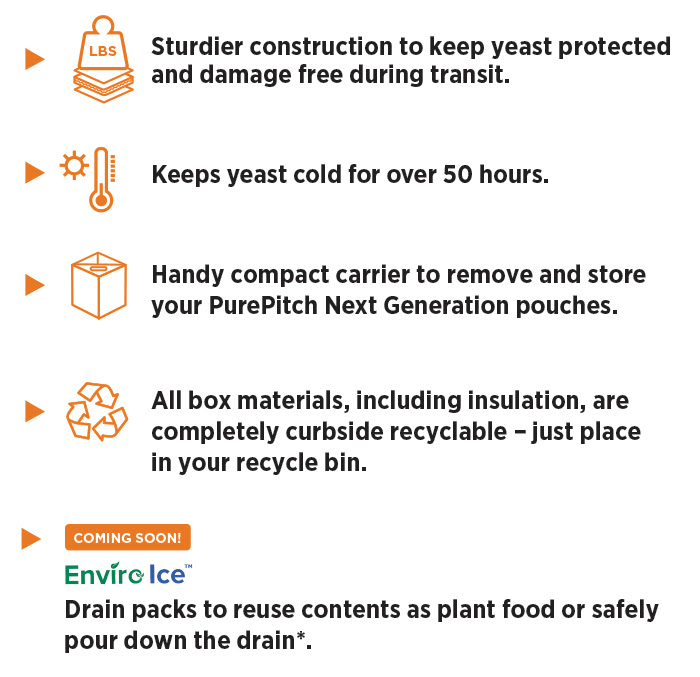

White Labs offers FedEx overnight and 2-day shipping to commercial customers and stores to most locations and FedEx International Priority outside of the 50 states. We offer alternative shipping methods upon request or when orders are placed on Yeastman.com; such as UPS and DHL (international only).

Boxes are insulated and contain gel ice packs for ideal transit and delivery temperatures.

Please place in refrigerated conditions immediately upon arrival.

Domestic homebrew store orders are shipped Wednesday for Friday delivery. Alternative ship days are available upon request or when orders are placed on Yeastman.com. Professional Brewery orders are shipped domestically, Monday through Thursday, and internationally on Thursday, Friday or Monday.

Cultivate your craft with the liquid yeast powerhouse.

Healthiest, most viable yeast, with the largest variety of yeast and 27 years of unparalleled innovation.

Yeast & Bacteria Bank

Yeast & Bacteria Bank

Enzymes & Nutrients

Enzymes & Nutrients

Lab Services

Lab Services

Education

Education

Merchandise

Merchandise