The Next Generation: Better Viability

From the beginning, White Labs has focused on high cell counts, high viability, and high strain diversity. In 1995, we coined the term “pitchable” as a way to bring a new type of liquid yeast into homebrewing and integrated into our strain numbers (WLP = White Labs Pitchable). The term ‘starters’ originated before White Labs, and was commonplace among homebrewers because liquid yeast culture packages designed to pitch into wort at ranges over 1 million cells/mL did not yet exist. As a result, it has evolved into a fascinating effort to obtain the best pitching rates for different beer styles.

RELATED: Stop Diacetyl in its tracks with Brewzyme-D

Still want to make a yeast starter? Click here for a quick 101!

One major difference with these early studies is that those estimators were based on other supplier cultures at the time, not White Labs Yeast. Since yeast is a living organism affected by thousands of variables, remember that this is very much an estimate. The only way to truly know the viability of any yeast culture is to use a microscope or other automated, expensive pieces of equipment and sound scientific techniques. The viability estimators are useful because they are based on packaged yeast and time/shelf-life studies.

"The only way to truly know the viability of any yeast culture is to use a microscope or other automated, expensive pieces of equipment and sound scientific techniques."

This improved our already-productive propagation for 2 main reasons:

- Heat-sealing the yeast inside the film for packaging created very little oxygen pick-up (compared to filling a bottle, for example). Oxygen lowers viability as yeast consumes it for the beginning lag phase and breaks down the stored glycogen that is so important for long-term storage.

- The film itself was created to release CO2 so it is not trapped inside the yeast package, and CO2 lowers viability because it is toxic to yeast cells.

"PurePitchⓇ Next Generation is also constructed with a thinner film, so it reduces our plastic use by 40%, supporting our strive better sustainability."

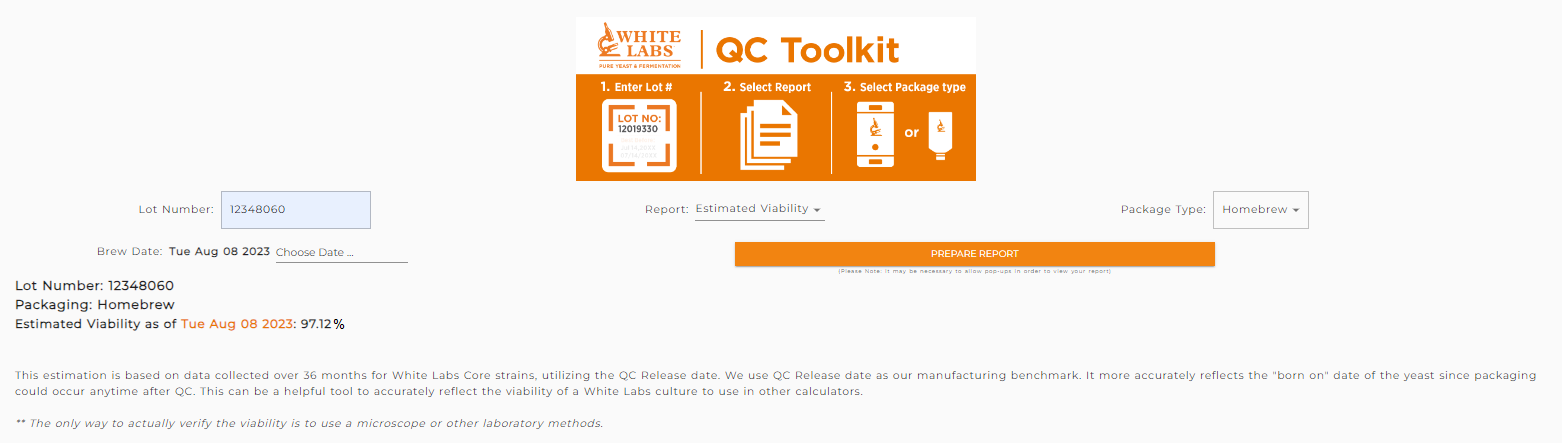

Along with this new technology, we have continued to evolve the White Labs estimated yeast viability calculator which we developed over time using data collected from all of our strains over the last 10 years. This large amount of data gives us great statistics for our packaging viability. This number can be plugged into any Pitch Rate calculator, giving you the best recommendation for how much yeast to use or what kind of starter to make.

To find our estimated yeast viability calculator scan our QR Code on PurePitchⓇ Next Generation packaging or enter the lot under the QC tab on Yeastman.com.

- TECHNICAL

- April 4, 2024

- TECHNICAL

- November 16, 2023

Yeast & Bacteria Bank

Yeast & Bacteria Bank

Enzymes & Nutrients

Enzymes & Nutrients

Lab Services

Lab Services

Education

Education

Merchandise

Merchandise