Is your CIP optimized for cleanliness?

Category : Technical

Date : November 16, 2023

Author : White Labs Brewing, Erin, Technical Brewer

Our dedication to exceptional quality at White Labs means we carry out the same standards and care for every batch for consistently superior products. That means constantly reevaluating our processes for a more effective cleaning program to maintain cleanliness. Changing processes means changing SOPs; documentation is typically the first thing to “fall through the cracks.” If you’ve ever found yourself questioning an SOP only to find that no one really knows why we do it this way, you’re not alone. Rapid growth and expansion increase the margin of error in your cleaning protocols, so re-evaluation is necessary. You can purchase the freshest hops the market has to offer, incorporate brilliantly exotic ingredients in your recipe, scale a mountain to source your water, and pitch the healthiest yeast into that fermentor. But if it’s not clean, it’s all for nothing. Sanitation isn’t a suggestion; it is the foundation for everything we do.

As part of the brew production team, we’re the first line of defense for contamination, tasked with CIP processes as well as supplying the proprietary clean wort needed for beer making. Using industry knowledge of proper CIP parameters, we took a deeper dive into the 4 arms of the Sinner’s Circle to optimize our SOPs. Devised by Chemist Herbert Sinner, the Sinner’s Circle describes the 4 factors of equipment cleanliness that are in the brewer’s control: Time, Temperature, Concentration, and Mechanics.

Time, Temperature, and Concentration are pretty straightforward. The mechanics of cleanliness is less obvious, so we tend to focus on the other three concepts. Simply put, mechanics refers to how equipment creates Mechanical Action in your tanks and process pipes, making this a fundamental component in effective sanitation.

What is Mechanical Action?

Mechanical Action refers to the shearing force of a solution across a surface or, in layman’s terms, your elbow grease. Let’s think about it like washing the dishes. If you use enough elbow grease, your dishes get clean. Anything less and your dishwashing skills need improvement, and organisms are still present. The difference in your dishwashing abilities is the breaking point between laminar and turbulent flow.

That line is the transition from laminar to turbulent flow. Laminar flow moves in straight lines. Turbulent flow moves in circles, and those circles are your scrubbing. In every pipe filled with liquid, including process piping, there are three zones of liquid: a boundary zone, a transitional zone, and a turbulent zone.

The boundary zone is the thin layer of liquid moving along the walls of your pipe, and as the speed of your liquid increases, the thickness of your boundary layer decreases, allowing your chemicals to reach the soils on the surface of your pipe. The speed necessary to penetrate that boundary layer is 5 ft/sec, which makes it your minimum required flow velocity. Benefits quickly diminish above 6.5 ft/sec, so 5-6.5 ft/sec is the sweet spot.

Finding the Sweet Spot: Flow Velocity & Reynold’s Number

Many of your process setpoints will be flow rates, so you'll need to do some calculations to determine if you are at the optimal mechanical speed of 5-6.5 ft/sec. Pump speed inputs are usually either a flow rate or a % Output (that output, by the way, is 60 Hz, so when you’re running your pump at 75% Output, you’re running it at 75% of 60 Hz). The value we need will be our flow velocity, which can be found using the following equation.

If you know your flow rate, you can determine your flow velocity.

Reynold’s Number

The Reynolds Number tells you whether your liquid flow is laminar or turbulent. Luckily, there are online calculators for this, but here is the equation: if the calculation is 50,000 or higher, you’re good to go!

All calculations are theoretical

| Flow Rate | ½ inch pipe | 1 inch pipe | 1 ½ inch pipe | 2 inch pipe |

| 60 GPM | 38,700 Re | 53,800 Re | 81,100 Re | 165,000 Re |

| 65 GPM | 41,900 Re | 58,300 Re | 87,800 Re | 178,000 Re |

| 70 GPM | 45,100 Re | 62,800 Re | 94,600 Re | 192,000 Re |

| 75 GPM | 48,400 Re | 67,300 Re | 101,000 Re | 206,000 Re |

Don’t Forget About Pressure Loss

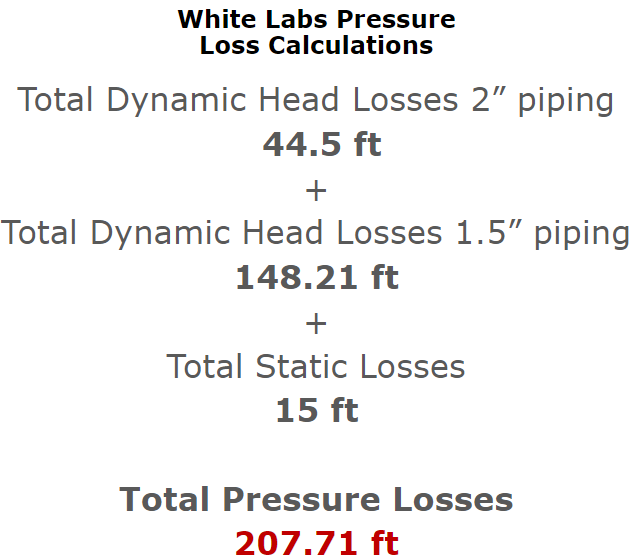

Since physics is hard, I summarized everything we learned into 4 words: Liquid has no breaks. If you’re driving on the interstate and want to get off at an exit, you’ll instinctively slow down because if you take that exit ramp at 80 mph, all four wheels may not stay on the ground. Liquid doesn’t know how to do that. The only thing liquid knows to do with a 90-degree elbow is crash into the walls of your process piping and cause friction, disrupting your pressure and flow. Suddenly, your flow isn’t so turbulent, meaning your scrubbing is subpar. It’s a much easier way to think about all of this stuff. In our system, we counted the total # of Ts, Elbows, branch lines, and reducers and measured both the length and static loss combined with our pump output.

Validation and Corrective Action

We verified this calculation by renting an UltraSonic Flowmeter to get 38 different readings from our process piping. The results were worse than I thought they would be. Everything in red is an insufficient flow, meaning I had much work to do.

| Measuring Point | Location | Filling Station | Flow Reading | Set Point |

| 1 | Kettle Arm | n/a | 31 GPM | 55% Output |

| 2 | Yellow Supply | CLOSED | 10 GPM | 75 GPM |

| 3 | Yellow Return | CLOSED | 9.5 GPM | 75 GPM |

| 4 | Blue Supply 2064 | CLOSED | 70 GPM | 75 GPM |

| 5 | Blue Return 2064 | CLOSED | 58 GPM | 75 GPM |

| 6 | Brewhouse Supply pre-T | n/a | 28 GPM | 85% Output |

| 7 | Brewhouse Supply post-T | n/a | 24 GPM | 85% Output |

| 8 | Green Supply 2628 | n/a | 21 GPM | 85% Output |

| 9 | Green Supply | CLOSED | 0.85 GPM | 75 GPM |

| 10 | Green Return | CLOSED | 0.80 GPM | 75 GPM |

| 11 | Green Supply 2620 | CLOSED | 15 GPM | 75 GPM |

| 12 | Green Supply 2624 | CLOSED | 10 GPM | 75 GPM |

| 13 | Green Return 2624 | CLOSED | 5 GPM | 75 GPM |

| 14 | Green Jumper 2628 | CLOSED | 4 GPM | 75 GPM |

| 15 | Green Jumper 2632 | CLOSED | 0.75 GPM | 75 GPM |

| 16 | Red Supply 2058 | CLOSED | 47 GPM | 75 GPM |

| 17 | Red Return 2058 | CLOSED | 48 GPM | 75 GPM |

| 18 | Red Supply 2006 | CLOSED | 2 GPM | 75 GPM |

I had a few choices - replace the CIP delivery pump, add a booster pump, or remove parts of the piping so our current pump could cover our losses. Due to the nature of our process, I could remove parts of the process piping without having to cut into the lines, and we’ve seen some awesome results with that. Below in figure 1. are some visual inspections of our piping from this continuous improvement plan with improving our flow rate.

Figure 1. Left, Green Supply 2628 taken on August 2022, visual sarkness can be seen in piping. Right, Green Supply 2628 taken on August 2023, metallic shimmer can be seen due to our improvements.

In addition to these line reductions, I updated our CIP logs with new validation standards and created a monthly audit program. Someone outside of operations ideally performs this audit. In our case, I turn this document over to our QA Manager, they perform the audit every month, and we discuss the results as a team. Reduced that risk of contamination and happy cleaning!

Conclusion Key Points

- Confirm that the pump is appropriately sized for your current process.

- Replace all soft goods/gaskets (Recommended every 6 months).

- Remove any unnecessary fittings or piping.

- Put validation systems in place for contamination (ATP Meter, Microbiological checks).

- Perform monthly audits to track.

- Document, document, document!

About the Author

Erin Maynard is the Technical Brewer at White Labs Inc., bringing expertise honed through her early career at two small breweries in Charleston, South Carolina. With a passion for craft beer, Erin combines technical precision and a creative touch to contribute to the world of brewing innovation.

- TECHNICAL

- April 4, 2024

Yeast & Bacteria Bank

Yeast & Bacteria Bank

Enzymes & Nutrients

Enzymes & Nutrients

Lab Services

Lab Services

Education

Education

Merchandise

Merchandise