Brew Your Best Beer with Zinc Buddy

What Are The Improvements To Fermentation With Zinc?

Can Yeast Ferment Without Zinc?

How Have Brewers Been Adding Zinc?

We worked with Lallemand 20 years ago to release Servomyces, which is a yeast culture grown in the process of very high zinc, and the zinc is taken up by the yeast, then heat killed. When added to the end of the boil, the yeast cells protect the zinc ions, and they are taken up by the live cells pitched into the cold wort. Servomyces works great — but a lot of brewers don’t use it. So, we wanted to find an alternative that people could use just as effectively as Servomyces.

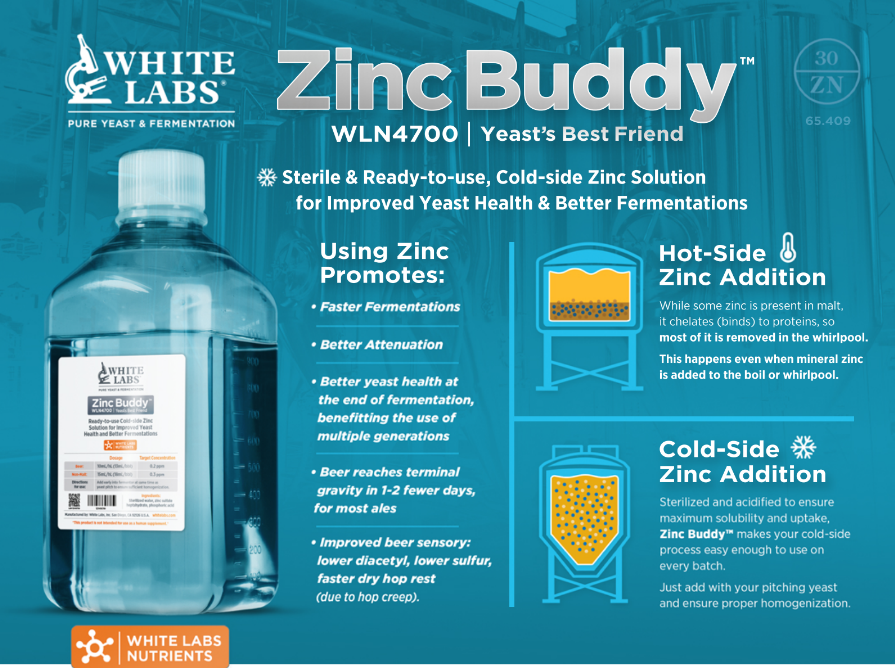

What is Zinc BuddyTM?

BUY NOW

Why Add Zinc To The Cold Side?

If There Are So Many Advantages On The Cold Side, Why Aren't More Brewers Adding It?

Why Not Just Add Zinc Versus White Labs Products?

Zinc can be toxic if not added at the right concentration (around 1ppm). Some zinc products, if added directly, can be very harmful and detrimental to yeast health. If you're using zinc in salt form, sterilization and acidification need to take place for it to remain in solution and keep contamination out. Proper equipment and knowledge of sterilization should be accounted for.

Zinc Buddy™ is made as a ready-to-use solution that takes the guesswork out of your cold-side zinc additions. Sterilized and acidified to a pH of 4 to ensure maximum solubility and uptake.

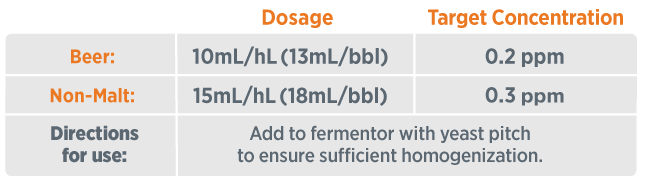

What is the dosage?

- Pro

This achieves 0.2 ppm zinc in cold wort at pitching time. It is assumed the wort has 0.1 ppm, so the total target starting Zinc is 0.3 ppm. Use the same for ales and lagers, in every batch.

Many brewers are now discovering the benefits of adding other things with the yeast right at the beginning of pitching, such as zinc, enzymes such as ALDC or Brewzyme-D, and Clarity Ferm. These White Labs products have been tested to White Labs standards for easy-to-use accessibility. Just spray the cap with isopropanol or sanitizer and loosen. Then carefully pour the desired volume of solution directly into the fermentor before knockout.

Calculate Recommended Nutrient Amounts For Your Next Brew

What Do You See In The Future For Cold Side Additions?

One way to do that is with our FlexPump, a peristaltic pump that’s designed to add yeast in-line on the way to the fermentor. With this pump, one could not only pitch their yeast for maximum homogenization but also add nutrients and things like purees in line. If you add it to the top of the fermentor, please do so as early as possible during the transfer. Mix well because enzymes and nutrients aren’t going to grow. They need to be well mixed to encounter the components they need to do their bio-activity.

Clarity Ferm is a good example of that. When people are using it to reduce gluten, they can have mixed results if they’re adding it to the top of the fermentor because of that mixing or lack thereof. We have some turbulence from the yeast growth and the fermentation. But it’s a different gravity than what you’re adding with the enzymes and nutrients. So, the mixing is not as complete as it would seem. And so you have much better results with Clarity Ferm, for example, when you’re adding it directly in-line into the fermentor and getting it well homogenized. So, whatever way you do that in your brewery is going to give you the best practice results. The same is true with zinc.

- TECHNICAL

- April 4, 2024

Yeast & Bacteria Bank

Yeast & Bacteria Bank

Enzymes & Nutrients

Enzymes & Nutrients

Lab Services

Lab Services

Education

Education

Merchandise

Merchandise