Quick Tips for Brewing Non-Alcoholic and Low Alcohol Beer

Category : Technical

Date : January 28, 2021

Author : White Labs Technical Team

Non-Alcoholic and Low Alcohol Beer

Non-alcoholic beer has been popular internationally for quite some time. More recently, the popularity of these beverages in the US has increased. This category spans beers ranging from <0.5% to about 2.5% ABV. Several methods are used to produce these methods. Not all of them are applicable to the craft beer market but it’s important to understand the different processes used.Vacuum Distillation

Larger breweries more commonly make these beers with some pricey equipment. One of the methods that produces a beer with <0.5% alcohol is vacuum distillation. This is a method in which the beer is heated and the alcohol is removed via the distillation process. This is a great way to reduce a beer with <0.5% alcohol but can produce a beer that has some undesirable off flavors. The heating process can produce off-flavors typical of beer that has been oxidized or with autolysis. Additionally, this equipment can be quite expensive for a craft brewer.Membrane Filtration

A second common method is a membrane filtration of a beer, very similar to the process of making RO water. This membrane specific for this process only allows alcohol, color, and some flavor and aroma compounds through the membrane. What results is alcohol and water is removed from the beer. Water is then returned to the concentrated beer. This methodology could be more approachable for smaller craft breweries as there are more accessible equipment coming to the market. One of the main cons with membrane filtration is that much of the flavor can be stripped along with the alcohol, but ultimately this can result with some of the best tasting results.Additional Methods

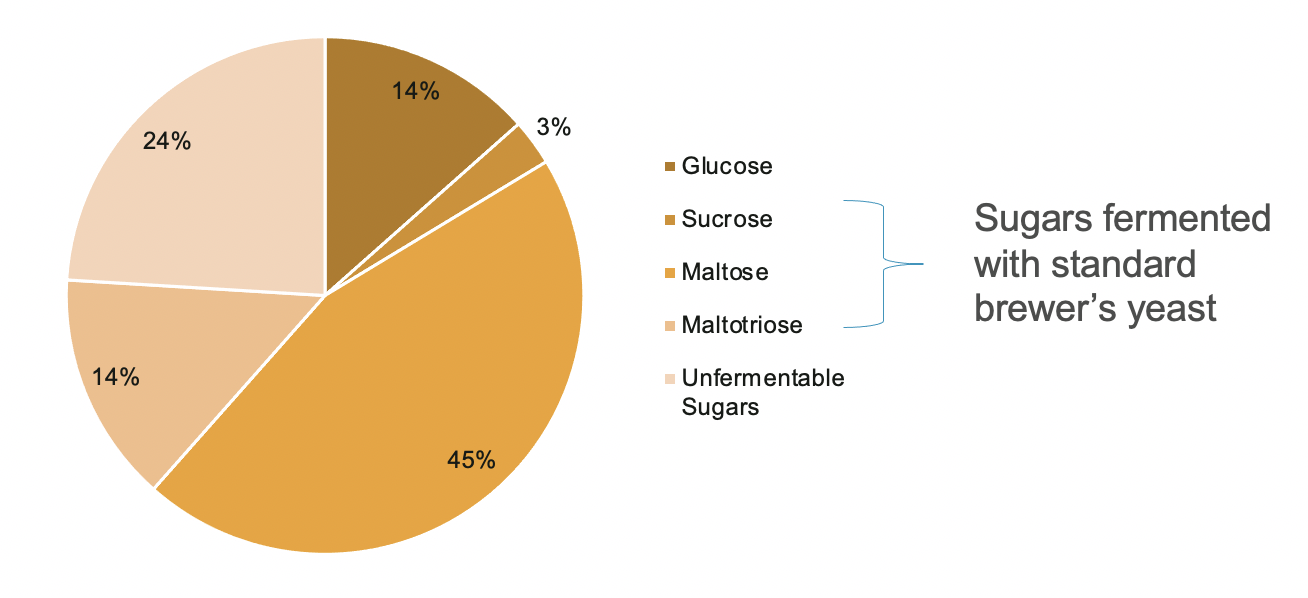

Altering the recipe or fermentation of a beer can be a good way to obtain low ABV beers, although achieving <0.5% can be more difficult. The first method would be altering the mash profile. Increasing or decreasing the mash temperature can create less fermentable sugars such as maltose and glucose.

Holding the mash temperature above 158°F will create more dextrins. This approach can produce a low alcohol beer but can also create a “worty” flavor and aroma. Cold mashing is another option in which the temperature of the mash is below starch gelatinization. Blending with water and increasing carbonation are two ways to combat the “worty” flavor.

Low Alcohol Yeast Strains

Low alcohol yeasts are a newer topic in the production of low alcohol beer. Many of these are non-Saccharomyces strains that cannot ferment maltose or maltotriose. When using these strains, a beer has to be designed to to have minimal amounts of glucose. All of these strains are non-GMO, although some strains do exist. Examples of low ABV strains that can be used in these types of fermentations:| Strain | Characteristics [1] |

| WLP618 Saccharomycodes ludwigii | Limited maltose and maltotriose consumption. A more neutral strain with some ethyl acetate production |

| WLP603 Torulaspora delbrueckii | Will not ferment maltose and maltotriose. Fruity, ideal for Belgian, saison styles or IPAs |

| WLP686 Zygosaccharomyces lentus | Partial inability to ferment maltose. More neutral but difficult to grow |

These strains can have positive contributions to flavor, such as increased esters, with additionally keeping the fermentation of fermentable sugars low. These will produce beers with an alcohol percentage of around 1-1.5% ABV depending on strain and wort recipe. Using these yeasts will certainly require a certain level of research and development to obtain a delicious, low ABV beer that can compete with products currently on the market.

Pitching rates of these strains can be expected to be lower, as the amount of sugar to be fermented is low. Pitch rates for these beers of lab-grown cultures range from 2-5 million cells/ml.

Non-Alcoholic/Low Alcohol Tech Sheet

References:

1.Capece, Angela & Romaniello, Rossana & Siesto, Gabriella & Romano, Patrizia. (2018). Conventional and Non-Conventional Yeasts in Beer Production. Fermentation. 4. 38. 10.3390/fermentation4020038.

- TECHNICAL

- April 4, 2024

- TECHNICAL

- November 16, 2023

Yeast & Bacteria Bank

Yeast & Bacteria Bank

Enzymes & Nutrients

Enzymes & Nutrients

Lab Services

Lab Services

Education

Education

Merchandise

Merchandise